|

|---|

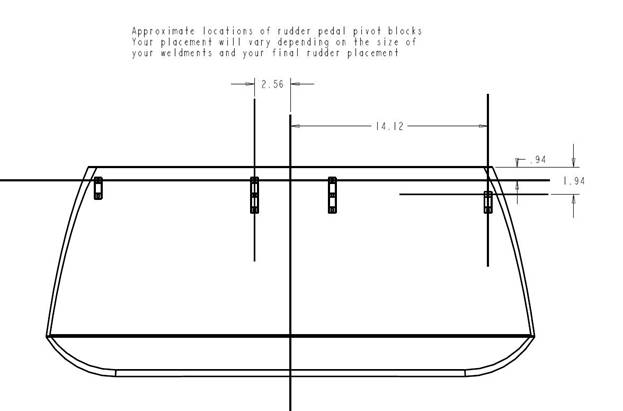

Rudder Pedals Before we can start work on the rudder pedals we need to determine their best location. I am a tall guy, 6' 3", so the Super2 will accommodate a wide range of pilot heights. The seat location should not be moved as the aircraft Center of Gravity was designed around the pilot in that location. If the aircraft is to be built for a shorter pilot, the rudder pedals should be moved aft, maintaining the pilot sitting position. If it is desired to have an aircraft for a range of pilot heights, it is best to place the rudder pedals to accommodate the tallest pilot, then use a seat cushion at the seat back to move the shorter pilot forward. It is required that W&B is performed for all pilot configurations that the aircraft will be flown. A Note of Caution: Extreme care needs to be exercised when getting into and out of the fuselage at this point in its construction. It is not fully stabilized structurally and a single foot bearing the full pilots weight at a single point on the fuselage bottom can damage the fuselage. Be very careful and enter gingerly, use your hands to support your weight on the fuse sides and be conscious of point loads on the airframe. The fuselage should be resting on the ground and should be supported under the seat area. The Super2 was designed assuming a 2" thick seat cushion at the seat back and the seat bottom. We will first install a pseudo spar to emulate the location of the spar box, through which the wing spar passes through the fuselage. We will then place a three inch thick box/crate or other spacer to emulate the seat bottom. Then we will use pillows or available seat pads to emulate the desired seat cushions. At this point the pilot can enter the aircraft and model the desired seating position and thus the desired rudder pedal position.

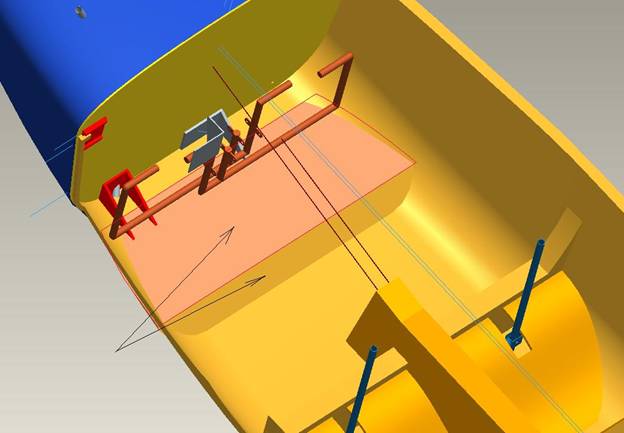

We will need the following drawings: Let us start with the heel rest. Take a sheet of ¼” last-a-foam and cut a piece that is roughly 12” by 35”. It will have to be trimmed to the curvature of the bottom of your fuselage. You are aiming for a heel rest with its forward edge 3 inches back from the firewall and touching the fuselage bottom. It will then be level in both horizontal directions. This will result in the rear edge being about 2.5” off the floor. A second piece will be fit to make a 45 degree angle to close off this open section to the rear. Slots will have to be cut in the front to clear the motor mount brackets. Below is a picture of the inside forward fuselage section with the heel rest highlighted. Cut four triangular pieces of ¼” foam with 1 BID on each side trimmed to act as supports for the heel rest. These will be bonded to the fuselage floor on edge and support the heel rest. Once you are happy with the fit of the heel rest, apply one BID to each side. Bond the four triangular supports to the fuselage floor, but do not bond in the heel rest at this time. Remember how we created a glass support for the horizontal stab on the rear of the fuselage? We will create the same thing for the heel rest on the four triangular supports. Once the supports are bonded to the fuselage bottom; they can be tacked into place with cyanoacrilic glue or a 5 min epoxy. Cover the bottom of the heel rest where they contact with duct tape, then lay a one BID strip of glass over it where the heel rest will contact the triangular supports. Lay the heel rest in place and let the glass cure. Once cured, remove the heel rest and add a one BID layer of glass to the supports. You now have a nice support platform for the heel rest.

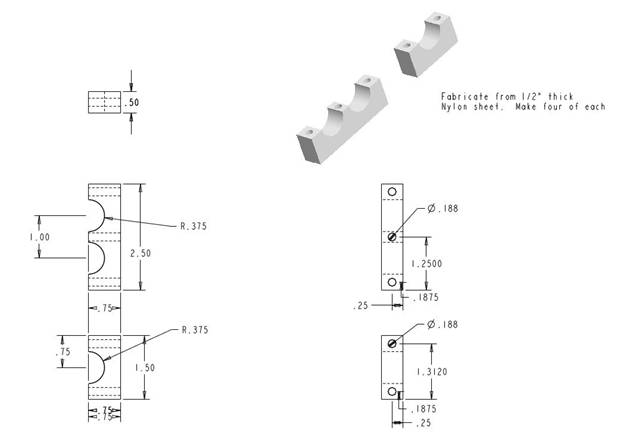

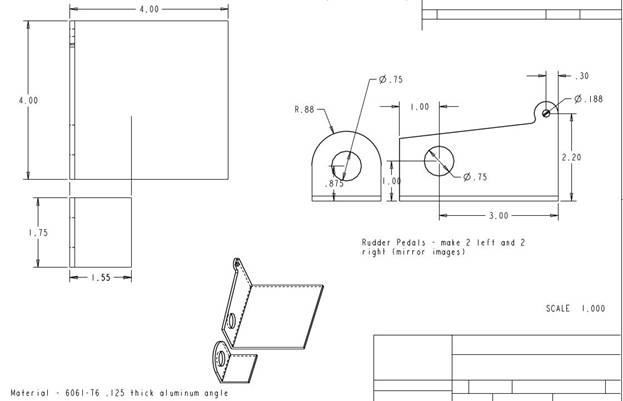

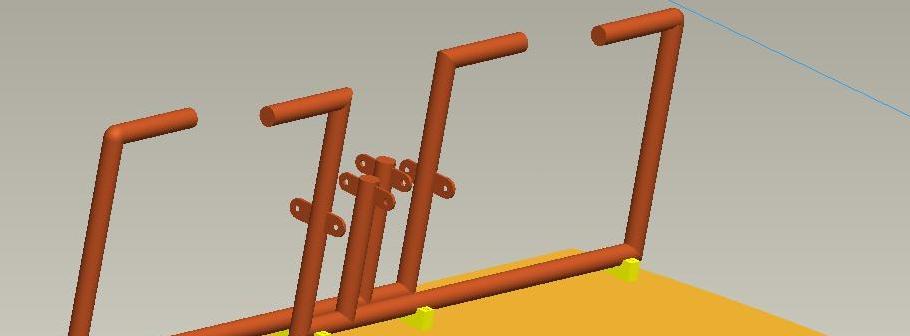

Cut four of these, place two of them end to end and drill the .188” holes all the way through. Use a bolt to clamp them together and then drill the large .75” hole. Be sure to use a drill press to insure the holes are perpendicular to the surfaces. Repeat the process for the four outer rudder pedal pivot blocks.

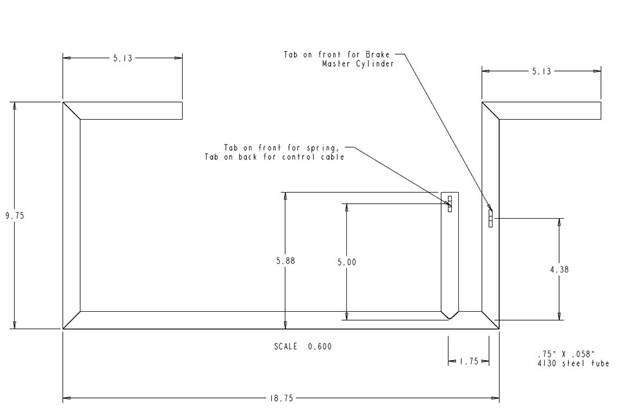

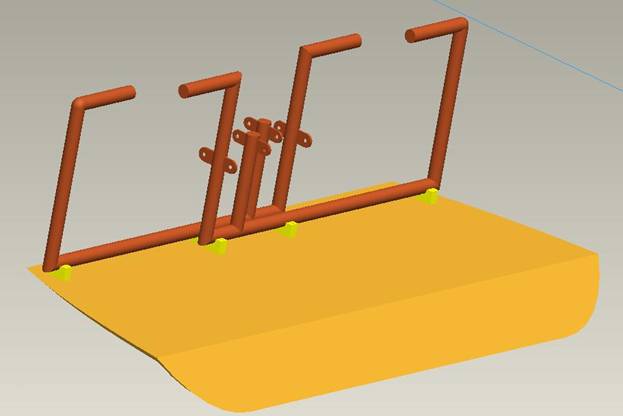

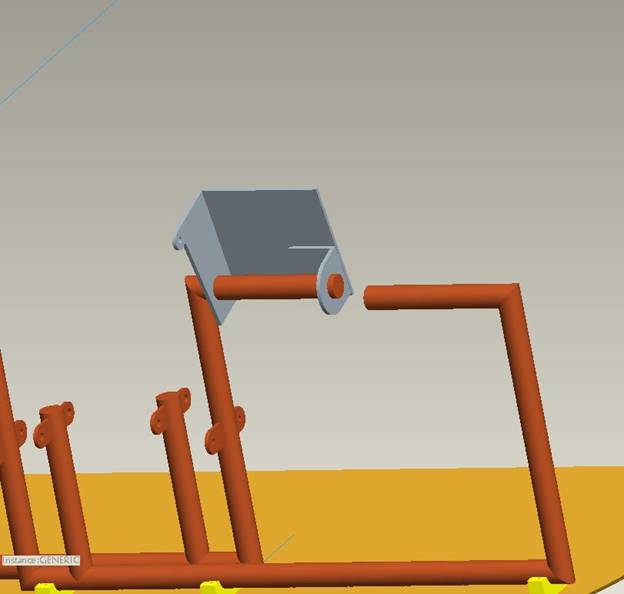

It is important to note that the tabs for the master cylinder are not welded in place at this time. They are welded after we have figuredout their best location, which is dependent upon the desired angle of the rudder pedal in its neutral position. We do not want the rudder pedal straight up and down as it is uncomfortable and will result in the brakes being applied when we are simply holding pressure on the rudder. Yet, we do not want the pedals tilted so far forward the brakes are difficult to apply. We will sit in the pilot seat and determine the optimal position (angle) for the rudder pedals then weld the tab into place.

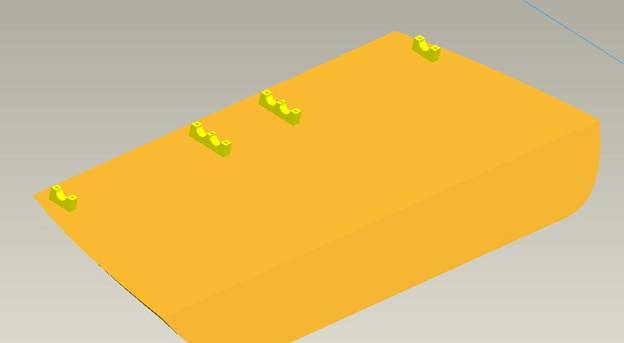

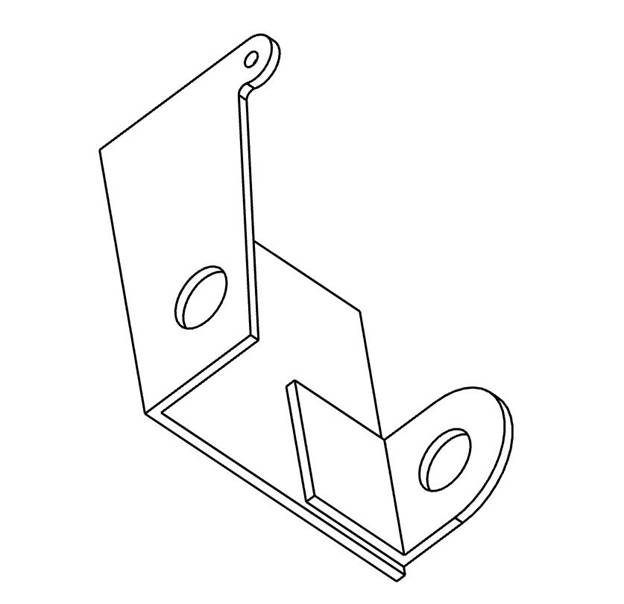

A pair of return springs are attached to the forward tabs and the firewall to keep the rudder cables taut. Rudder Pedals. The rudder pedals are fabricated from a section of 2.5” X 4” X 1/8” 6061T6 Aluminum angle – ACS 03-48675. Use the following drawing to fabricate two left and two right pedals. Don’t make four left pedals! The rudder pedals are fabricated from a section of 2.5” X 4” X 1/8” 6061T6 Aluminum angle. Print out the patterns and cut the pedals. Lightning holes may be added. The secondary angles are riveted into position with #30 rivets. Finally, the pedals are held in place with a section of .75” pvc sprinkler pipe attached to the rudder weldment with a single AN3 bolt drilled vertically through the weldment. Remember, the bolt goes through the top and the nut goes on the bottom. Always think, if the nut were to fall off, would the bolt remain in position?

The smaller part is then riveted on the back of the pedal as shown below. Use a section of ¾” tubing to help align it while drilling the rivet holes.

The pedal is held in place with a section of ¾” pvc water pipe and a single AN3 bolt through the rudder pedal weldment.

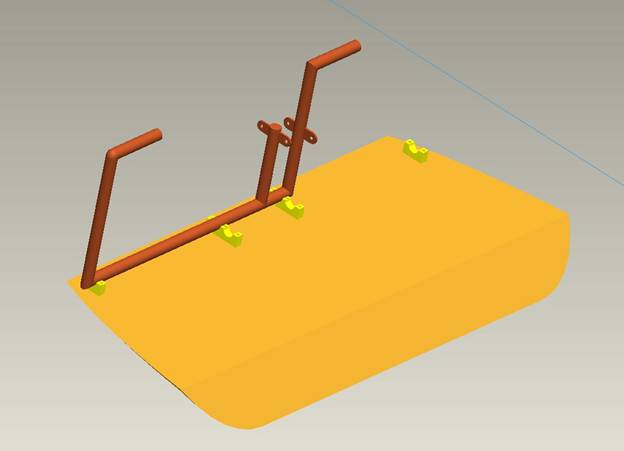

The short arms in the middle will attach to the rudder cables that run down the center of the aircraft.

PREVIOUS<---------------Manual Home ------------------>NEXT |