| |

|

Home

The Manual

Downloads

Contact

Disclaimer |

|

|

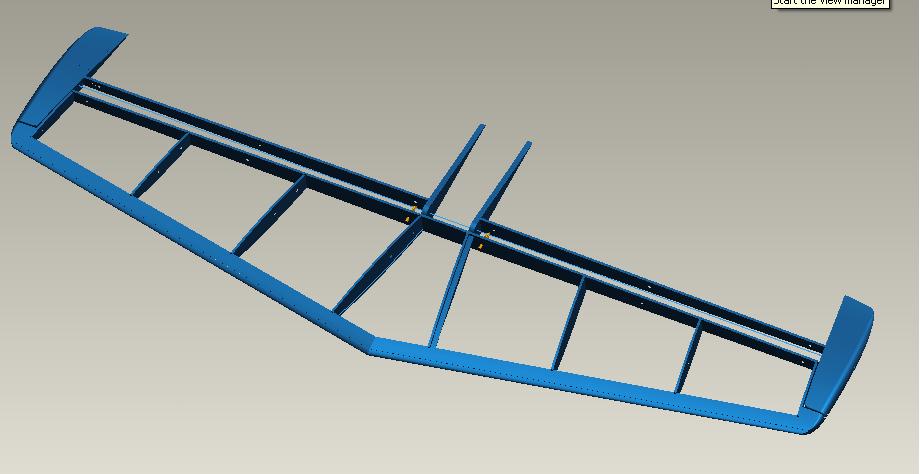

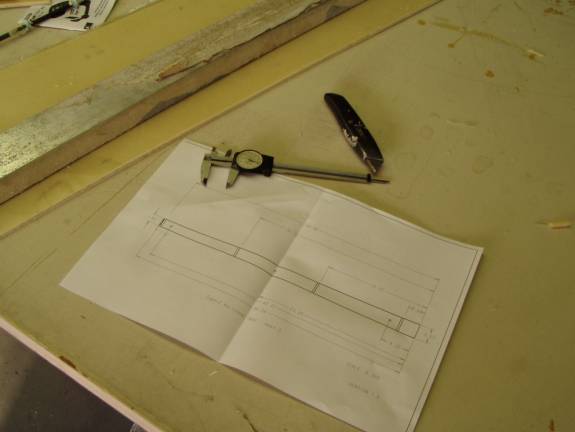

Horizontal Spar and Elevator Spar Fabrication

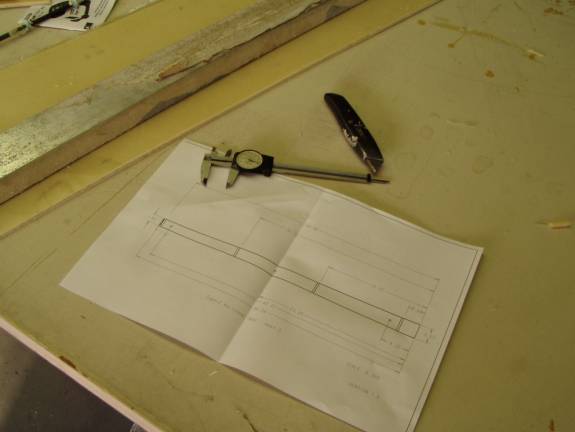

Print out Spar Drawings

Print out the Drawings for the Horizontal

Spar and Elevator Spar. Study

the drawings and understand the layout. The spars are symmetrical

about a center line running through the mounting holes for the hinges. We

will cut a tapered piece from the ¼ glass and foam sandwich

made earlier. We will sand the edges so they are straight,

then we will cut the ends to achieve the proper spar width from center

to end. Finally we will mark the locations of the four ribs

and hinge mounting holes.

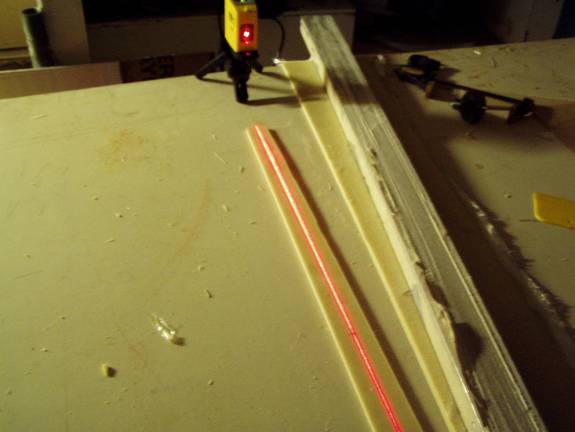

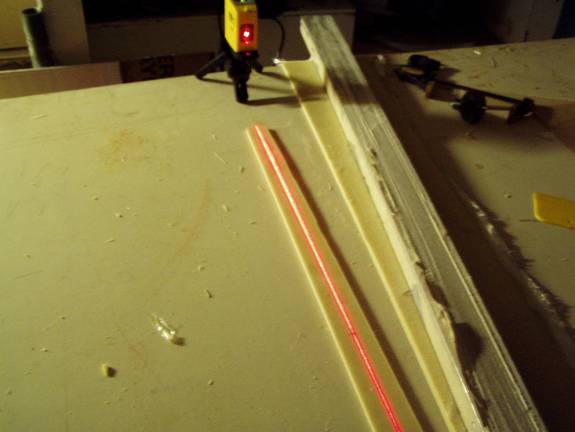

Clamping Scheme for Long Straight Cuts

An indispensable tool that will be used throughout the build is

a piece of aluminum box tubing about five or six feet long. Here

it will be used as a solid straight edge, later it will be used as

a long sanding block to shape the flying surfaces. Clamp

the straight edge to the table over the long stock of ¼” glass

foam sandwich made earlier. First make a clean edge. Then

mark the ends and make your second cut resulting in a spar half.

The technique for cutting straight pieces from our stock is as follows:

- Insure that the straight edge is securely clamped to the raw

stock and the table. Check the position of the blade against

the straight edge to insure the cut will be made where you want

it.

- Draw the razor knife toward you with both the razor blade and

the knife body solidly against the box tubing straight edge. Be

careful, know where the knife blade will go if you slip.

- Use a slight inward bias of the blade toward the straight edge

so the knife does not wander away from the straight edge as you

make the cut.

- Use moderate pressure to repeatedly score the fiberglass. Do

not attempt to make the cut in one pass. Take several light

pressure passes to cut through the glass layer.

- Our intention is not to cut all the way through, just cut through

the top layer of glass, do not worry about cutting through the

foam. The knife is not perpendicular to the cutting surface

and if you attempt to cut all the way through your cut will be

angled.

- Once you have cut all the way through the top glass layer, unclamp

the straight edge and score a couple of inches all the way through

the stock at each end.

- Flip the raw stock over and again clamp the straight edge to

the stock. Use the knife held in the proper cutting position

against the straight edge and in the cut marks made all the way

through the stock to align your straight edge.

- Make the cut on the back side as you did on the front side. Again

do not worry about cutting all the way through the foam, just the

layer of fiberglass. When the piece is cut, it will pull

away from the stock. The foam does not need to be as straight

as the foam along and edge will most likely be dug out and replaced

with micro at some point anyway.

- Using a sheet of sandpaper laying on the table to lightly sand

the entire edge. Drag the part uniformly over the sandpaper using

even pressure. We don’t want to take a part that is

straight and sand a curve into the ends.

- Nice Job. Admire your straight edge.

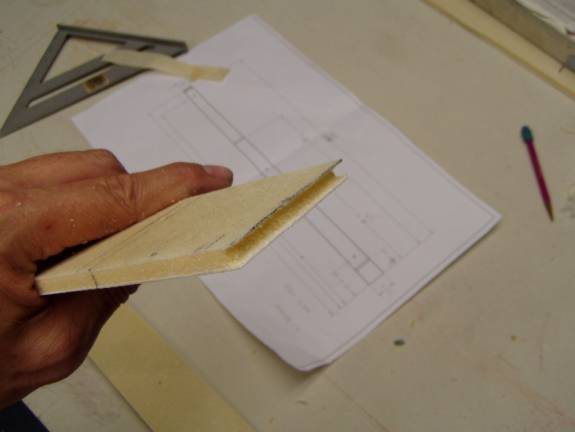

Spar Stock

Set up for the Next Cut

You can cut the pieces a little wider than necessary, it is easy

to sand them down to size later. Go ahead and cut all four

spar pieces, the two elevator spars and the two horizontal spar

halves. Use your calipers to decide where to cut the ends

so the spars are the proper length with the proper width at each

end. Put the left over panel stock asside, there should be enough

to cut the vertical fin and rudder spars later.

Marking the Center of the Spars

Another indespenisble tool is the laser level. Get one that

can create both horizontal and vertical lines and a unit that is

self leveling is a time saver. This will be used extensively

in the building and jigging of the fuselage

.

Measuring in from the side, define the center line of the spar. Mark

this, as this will be uses later to alighn the complete horizontal

assembly. Locate the hinge holes and make lines to mark the

rib locations. Drill #30 guide holes to mark the hinge locations.

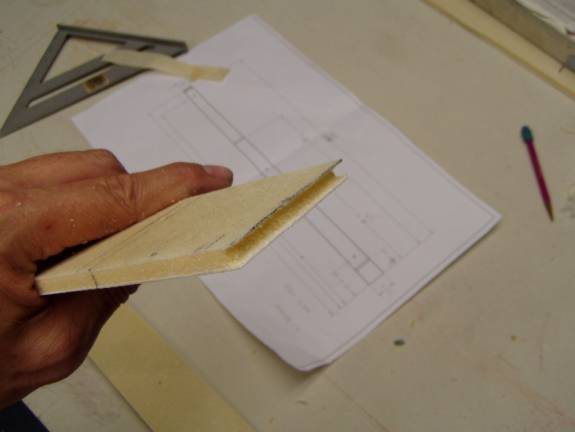

Spars Cut Out

Label each spar half as to port or starboard, (or pilot side and

co-pilot side), top and bottom. From this point forward

we want to maintain proper orientation of the horizontal spar and

the pairing to the elevator spars. The hinge locations will

be match drilled.

Aligning Spar Halves

We will now join the two horizontal spar halves. Find a flat

spot long enough to work on the entire spar. Use the laser

level to insure the spar is perfectly straight. Place some

plastic wrap under the joint so you don’t glue the spar to

the floor.

Remove Foam Core at Joint

Dig out about a ¼” of the foam from the center section

of the two horizontal spar halves.

5 Minute Epoxy

Mix up a batch of 5 minute epoxy and flox to a thick buttery consistency.

Work the mixture into the ends of the spar halves and squeeze together. Work

fast before the epoxy cures.

Cutting Cloth on the 45 Bias

Use the laser level to insure the horizontal spar is perfectly straight. Use

masking tape to hold the spar in place while the epoxy hardens. It

will not take long.

Surface Prep

Once the epoxy has cured, sand the joint and clean it with acetone.

2 BID Joint

Lay a two BID layup extending about 2 inches from each side of the

joint. Flip the spar over and layup the other side in a like

manner. Use masking tape and the laser level to insure proper

alignment and let the glass cure.

Creating Plywood Hardpoints

Take a sheet of 3/32” or ¼” aircraft grade birch

plywood and using a 1 inch hole saw, cut about 20 hard point buttons.

Horizontal Spar and Elevator Spars

Once the spar joint is cured we are ready to install the hinge hard

points.

Hole for Hardpoints

Use the one inch hole saw to cut out the glass layer on the forward

side of the horizontal spar and on the rear side of the elevator

spars. Do not cut all the way through the spar, ONLY cut through

the top layer of glass.

Remove Glass and Foam from One Side

Dig out the foam in the hole.

Installing Hardpoint

The hard point buttons will be installed with a thick micro. Two

layers of BID will be layed up over the hardpoint and one layer of

BID will be layed up on the reverse side of the spar.

Preparing to Bond in Hardpoints

Prepare your work area and materials-sandpaper, acetone, hard point

buttons and fiberglass. Cut out a pile of 4” square

pieces of fiberglass. Lay down plastic wrap on your work surface

as mold release.

Hardpoints Curing

The hinge hard points are installed as follows:

- Use sandpaper and Acetone to clean the fiberglass on both sides

of the spar around the hard points.

- Mix up a moderate batch of thick micro using about 25 grams of

resin.

- Using a tongue depressor, work the micro into each hard point

cutout in the spars.

- Press the hard point buttons into the hardpoint cutouts.

- Use the tonge depressor to level the micro across the top of

the hard point. Do not worry about micro filling the hole

in the middle of the button, this will be drilled out later.

- Clean the micro from the fiberglass surface every where except

over the button itself. It is important to remember that

we never want micro between layers of fiberglass as this significantly

weakens the joint.

- Layup two layers of BID over the micro-ed button. The glass

should extend over the edge and about 2” beyond the button

on each side.

- Flip the spar over and clean the micro from the back side if

any has squeezed through the hinge holes.

- Layup one BID layer over the hinge hole on the back side, again

the glass should extend over the edge and about 2” beyond

the button on each side.

- Let the glass cure.

|

|

|

|

|

|