Chapter 7 - The Wing

Section 4 - Wing Internals

Post Curing the Wing Bays

The wing is a large structure and takes some special techniques to post cure. It is impractical to enclose the entire wing in a chamber and bake it so we have to do it incrementally. The spar and ribs have already been post cured, so our next task is to post cure the inside of the wing bays. I found the easiest way to do this was bay by bay. I post cured while I was working on other area of the plane. Remember to support the wing during post curing operations. All level lines on all ribs must remain level through out any post curing operation. Supporting the wing root at the spar and the wing tip is usually sufficient.

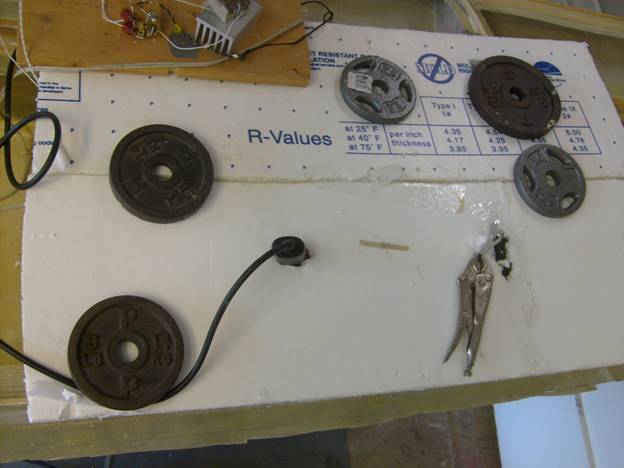

Below is the simple set up I used to post cure the bays. The foam is 1” thick polystyrene sheet costing about $10 for an 4’ X 8’ sheet. A single sheet that covers the bay and a heat gun for the heat source, a metal measuring cup as a heat deflector are used. In the picture you can see the handle of the cup being held by the vise grips. The cup is put in the air stream of the heat gun in an attempt to diffuse the heated air flow. I also have a fan in the bay that is continually running to stir the air. At the top of the picture is a thermostat that turns on the heat gun at 150 degrees or below,and turns it off at 160 degrees and above.

Later we will have to post cure the wing skin. This is done in sections. We will essentially build our post curing oven on top of the wing skin and post cure it a bit at a time. But more about that later....

Complete.