Composite Material Construction Techniques

DON'T SKIP THIS SECTION. Every hour you spend in this preparation section will save you five when you really start building your aircraft.

INTRODUCTION

In this section you won't build any part of your airplane. What you will do is learn how to build your airplane the right way. The construction techniques may be radically different from anything you've done before (including building boats, surf-boards, airplanes, and gocarts), and you should assume there is only one correct way to do it. We've discovered many wrong ways of doing things and have written the plans to keep you from repeating our mistakes. We insist that you do things our way. If you have a better idea, suggest it to us; we'll test, and if it really is a better idea we'll publish details in the Quickie Newsletter.

This section will teach you all of the techniques required to build your airplane, show you what special tools you need, and how to use them. The educational samples that you will build in this section are designed to give you experience and confidence in all of the techniques that you will use in the construction of your airplane. The steps in construction of each sample are arranged in sequence (as are the steps in construction of the actual aircraft parts) and you should follow the sequence without skipping any steps. You will learn the basic glass layup technique used throughout the aircraft, special corner treatments, foam shaping/cutting, and joining methods. A summary of these techniques is provided on yellow paper for you to tack up on your shop wall.

THE FOLLOWING TOOLS ARE ONES YOU MAKE:

Sanding Blocks

These are required in many areas during construct-ion and for finishing. You may also use a "soft block", which is a block of the blue-white or orange styrofoam wrapped with sandpaper.Much elbow grease is saved if you replace the sandpaper often.

Long Straightedge This is not absolutely required, but is quite

handy when jigging or checking the straightness of flying surfaces. It is merely a 6-ft or 8-ft 1x3 or 1x4 piece of lumber that is hand-selected to be "eye-ball straight". You can get it one of two ways: (1) Order it from Aircraft Spruce & Speciality Co., or Wicks Aircraft Supply - they plane them perfect from dry lumber. (2) Sort through the lumber (dry fir or redwood) at your local lumber yard until you find one that looks straight when you eyeball it from one end. Mark it and hang it on the wall so it doesn't end up as part of a shelf!

Epoxy Balance

Devices which automatically ratio the correct amount of resin and hardener and dispense it with the pull of a lever are available from Aircraft Spruce & Speciality Co., and Wicks Aircraft Supply. A digital scale and calculator work very well. A scale with a TARE feature helps as it will subtract the weight of the cup and then the resin for you. The calculator is used to figure out the amount of hardner is required for the given amount of resin poured.MATERIALS

The materials, processes, and terminology used in the construction of your Super2 are recent to home-building. This section is devoted to familiarizing you with the language, materials, and techniques used in these plans. This information is basic to the construction of your airplane. You should study this section and be sure that you understand all of it before continuing.

There are five basic materials that you will be working with: fiberglass cloth, epoxy, microspheres, flox, and foam. Each material, its properties, and uses, will be discussed in detail. Basic processes using these materials will also be discussed.

Fiberglass Cloth

The most basic structural material in your Super2 is glass cloth. Glass cloth is available commercially in hundreds of different weights, weaves, strengths, and working properties. The use of glass in aircraft structures, particularly structural sandwich composites, is a recent development. Very few of the commercially available glass cloth types are compatible with air-craft requirements for high strength and light weight. Even fewer are suitable for the handlayup techniques used in the Super2. The glass cloth used in the Super2 has been specifically selected for the optimum combination of workability, strength, and weight.

The glass cloth in your Super2 carries primary loads, and its correct application is of vital importance. Even though doing your glass work correctly is import-ant, this doesn't mean that it is difficult.

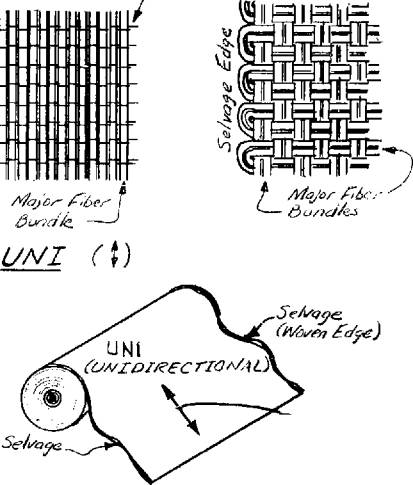

Two types of glass cloth are used, a bi-directional cloth (5277BID), and a unidirectional cloth (5177UND). (Use the full part number for ordering your cloth, but for simplicity the plans will use only BID or UNI designations). BID cloth has half of the fibers woven parallel to the selvage edge of the cloth and the other half at right angles to the selvage, giving the cloth the same strength in both directions. The selvage is the woven edge of a bolt of fabric as shown in the accompanying sketch. These fiberglass cloths were developed and proven by Burt Rutan and use his name.

UNI cloth has 95% of the glass volume woven parallel to the selvage giving exceptional strength in that direction and very little at right angles to it. BID is generally used as pieces which are cut at a 45-degree angle to the selvage and laid into contours with very little effort. BID is often applied at 45 degree orientation to obtain a desired torsional or shear stiffness. UNI is used in areas where the primary loads are in one direction, and maximum efficiency is required, such as the wing skins and spar caps. Multiple layers of glass cloth are laminated together to form the aircraft. structure. Each layer of cloth is called a ply and this term will be used through-out the plans. Marking and cutting the plies of glass cloth is a job that you will repeat often in the construction of your Super2. Glass cloth should be marked, cut, and stored in a clean area with clean hands and clean tools. Glass contaminated with dirt, grease, or epoxy should be discarded. A clean, smooth surface is needed for marking and cutting. The area used for storing and cutting glass cloth should be separated from the air-craft assembly area because otherwise it mill be. exposed to foam dust, epoxy, and other things which can contaminate the cloth. You will need a good sharp pair of scissors, a felt-tipped marker, a fairly straight board, and a tape measure for marking and cutting. The small amount of ink from marking and numbering plies has no detrimental effects on the glass cloth. In each step the size, type, and fiber orientation of each ply is given. Take the list to your glass cutting table, roll out a length of the appropriate cloth, straighten the selvage, mark all of the plies, and cut.

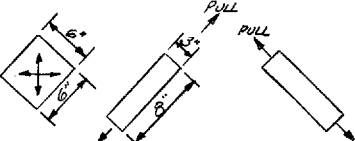

Now is a good time to stop reading long enough to go and cut a square ply of BID and see how easy it is to change its shape by pulling and pushing on the edges as shown in the sketches. Cut a square with the fibers running at 45° and pull on the edges to shape the piece.

It helps if you make fairly straight cuts, but don't worry if your cut is within 2 inch of your mark. As you cut BID, it may change shape, just as the square ply that you are experimenting with does when you pull on one edge. Plies that distort when cut are easily put back into shape by pulling on an edge. Rolling or folding cut plies will help keep them clean and make it easier to maintain their shape. If several plies are called for, it may help to number them before cutting. Save your clean scraps and make an effort to use them for smaller plies. If the cloth is spotted with epoxy, throw it away.

When cutting long strips or large pieces of 45-degree BID, always roll or fold it so it keeps its shape when handled. When it's applied, it can be set on one end of the part and rolled onto it. If you pick up each end, it will distort and not fit the part properly.

The fiber orientation called for in each lamination is important and shouldn't be ignored,. UNI is characterized by the major fiber bundles running parallel to the selvage and being much larger than the small cross fibers which run at right angles to the selvage. In BID the cross fibers are the same size as those running parallel to the selvage, giving BID an even "checker-board" appearance. BID is commonly used for plies cut at 45° to the selvage. Your tailor would call this a "bias" cut. The 45° cut makes it easy to work wrinkles out of a ply locally, without having to chase it to the far edge. The 45° cut also makes it possible to make a ply slightly longer than originally cut by pulling on the ends, or wider by pulling the sides. The 45° orientation isn't critical; you don't need to measure it. Your eyeball of a rough diagonal (45° ± 10°) is adequate when either cutting or laying up the cloth.

EPOXY

In recent years the term "epoxy" has become a household word. Unfortunately, "epoxy" is a general term for a vast number of specialized resin/hardener systems, the same as "aluminum" is a general term for a whole family of specialized metal alloys. Just as the "aluminum" pots and pans in your kitchen, the "epoxy" in your Super2 is vastly different from the hardware store variety.

Epoxy is the adhesive matrix that keeps the plies of load-carrying glass cloth together. Epoxy alone is weak and heavy. It is important to use it properly so that the full benefits of its adhesive capability are obtained without unnecessary weight. A large portion of your education in composite structural work will be spent learning how to get the full strength of an epoxy/glass mixture with the minimum weight. This section will discuss the terminology and techniques for working with epoxy resin and its hardener.

An "epoxy system" is made up of a resin and a hardener tailored to produce a variety of physical and working properties. The mixing of resin with its hardener causes a chemical reaction called curing, which changes the two liquids into a solid. Different epoxy systems produce a wide variety of solids ranging from extremely hard to very flexible. Epoxy systems also vary greatly in their working properties; some are very thick, slow pouring liquids and others are like water. Some epoxy systems allow hours of working time and others harden almost as fast as they are mixed. A single type of resin is sometimes used with a variety of hardeners to obtain a number of different characteristics. In short, there is no universal epoxy system; each has its own specific purpose and while it may be the best for one application, it could be the worst possible in another use.

The epoxy systems used in the construction of your Super2 are tailored for a combination of workability and strength, as well as to protect the foam core from heat damage and solvent attack. These systems are very low in toxicity to minimize epoxy rash. The epoxies are not. similar to the common types normally marketed for fiberglass laminating. Two different systems are used in the Super2: a normal curing system, and a 5-minute system. The very fast curing (5-min.) system is used much like clecos are used in sheet metal construction (or clamps in woodwork); for temporary positioning. Five-minute is also used in some areas where high strength is not required, but where a fast cure will aid assembly.

Aeropoxy PR2032 and PH3660 will cure to a firm structure at room temperature within one day. Complete cure takes several days and the epoxy may be heat cured for additional strength. This is done at elevated temperature of 150 to 160 degrees F.

5 minute epoxy can be used on any foam bonding where parts are small- and the fast cure allows the next step to be done soon. Also used as a temporary joint for jigging.The working and strength characteristics of an epoxy system are dependent on the resin, the hardener, and on the amount of each in a given mixture. Epoxy systems are engineered for a specific ratio of resin and hardener. It is quite important that the proper mixture be obtained. An accurate balance or ratio pump must be used to accomplish this. The mix ratio accuracy is particularly important with Aeropoxy. The 5-Min. can be adequately rationed by merely pouring a blob of part A in a cup and adding a blob of part B that looks the same volume before mixing. Never eyeball or estimate Aeropoxy, always carefully use the balance or pump.

Epoxy resin and hardener are mixed in small batches, usually 6 ounces or less, even in the largest layup. The reason for small batches is that, in large batches, as the hardening reaction progresses, heat is generated which speeds the reaction, which causes even more heat, which ends up in a fast reaction called an exotherm. An exotherm will cause the cup of epoxy to get hot and begin to thicken rapidly. If this occurs, throw it away and mix a new batch. The small volume batch avoids the exotherm. For a large layup, you will mix many small batches rather than a few large ones. With this method you can spend many hours on a large layup using epoxy that has a working life of only a few minutes. If the epoxy is spread thin as in a layup its curing heat will quickly dissipate and it will remain only a few degrees above room temperature. However, in a thick buildup or cup, the low surface area to mass ratio will cause the epoxy to retain its heat, increasing its temperature. This results in a faster cure causing more heat. This unstable reaction is called an exotherm. Exotherm temperatures can easily exceed the maximum allowable for foam (200°F) and damage the foam-to-glass bond.

Unwaxed paper cups are used for mixing and ratioing resin and hardener. Convenient 8-oz cups for resin are provided. The hardener cups are the 3-oz unwaxed bathroom paper cups. Don't use waxed cups; the wax will contaminate your epoxy.

Mixing is done by stirring with a stick, being careful not to spill any. If you spill part of an unmixed cup, the ratio of resin and hardener may be inaccurate and it shouldn't be used. Mix each cup for at least two minutes. You should spend 80% of your mixing time stirring the cup and 20% scraping the sides to assure complete mixing. Do not mix with a brush. The bristles can soak up the hardener, changing the ratio. Use a tongue depressor or wood stick. The working temperature has a substantial effect on the pot life and cure time. Very hot conditions will cause the cure to speed up. -In cold working conditions the cure will be delayed and if it is cold enough, epoxy may not cure at all. Working temperatures must be between 70° and 90°F. A range of 75 to 80°F is best. Be sure to get a wall thermometer (approx. $1.50 at any general store) to check the temperature of your work area. At 75°F, 5-Min must be used within four minutes, and Aeropoxy must be used within 20 minutes.

Cold epoxy results in increased time required to do a layup, since it takes longer to "wet" and to squeegee the cloth. A layup at 65° may take almost twice the time as at 75°F. On most layups (except for joining foam cores) its best to have 75 to 80°F room temperature and 80 to 90°F epoxy. Resin and hardener can be kept warmer than room temperature by keeping it in a cabinet with a small light bulb on. DO NOT store your resin or hardener on a cold floor if you plan to use it within the next several hours. If you let your shop get cold between working periods, keep some resin and hardener in the warmest place of your house for use on the next layup.

Save your mixing cups, as they can be used as a quality check of your epoxy. After a day or two take a sharp knife point or scribe and scratch the surface of epoxy in the cured cup. If the epoxy cured properly, the scribe will make a white scratch mark. If the epoxy hasn't cured, the scribe will make a dull ridge, indicating a soft surface. If this occurs, the epoxy has not cured, either due to inadequate time or temperature, or bad mixing, or bad epoxy.

MICROSPHERES

Microspheres are a very light filler or thickening material used in a mixture with epoxy. Micro, as the mixture is called, is used to fill voids and low areas, to glue foam blocks together, and as a bond between foams and glass skins. The glass bubble-type supplied is lighter than most common types. Microballoons must be kept dry. If moisture is present it will make them lumpy. Bake them at 250°F; then sift with a flour sifter to remove lumps.

Micro is used in three consistancies; a "slurry" which is a one-to-one by volume mix of. epoxy and micro-spheres, "wet micro" which is about two-to-four parts microspheres by volume to one part epoxy, and "dry micro" which is a mix of epoxy and enough microspheres to obtain a paste which will not sag or run (about five parts-to-one by volume). In all three, micro-spheres are added to completely mixed epoxy.

You do not have to accurately mix the micro-spheres; just dump them in until the desired consistency is obtained. Micro slurry is used to paint over foams before glass cloth is applied over them. Slurry is almost the same viscosity as.the pure epoxy and is runny enough to apply with a brush. However, the easiest way to apply slurry is to pour it onto the surface and spread it out evenly using a squeegee. When skinning urethane foam use a full thick coat of slurry. Inadequate slurry on urethane can result in a poor skin bond. Wet micro is used to join foam blocks, and, while it is much thicker than slurry, it is still thin enough to sag and run (like thick honey). Dry micro is used to fill low spots and voids and is mixed so that it is a dry paste that won't sag at all. In all three micro types, you don't measure, just add micro-spheres until the desired consistency is obtained. Use micro only as specifically shown - never use micro between glass layers.

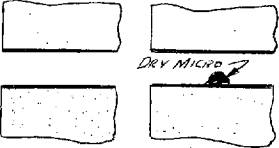

Always use the following method to join foam blocks. This is extremely important.

- Check that the foam blocks fit closely together. If there are voids over 1/16 inch, sand to fit, or fill the void with a sliver of foam.

- Paint a light coat of micro slurry on both surfaces. If joining foam to fiberglass, paint pure mixed epoxy (no microspheres) on the fiberglass surface and micro slurry on the foam surface.

- Refer to the sketch and trowel wet or dry micro in the center of the joint. Thus when joined the micro is pushed outward expelling (rather than trapping) air. If the fit is excellent use dry micro.

- Push the two pieces together, wiggling each to move the micro toward the surfaces. Be sure the micro is no thicker than 0.1 inch at any place, to avoid exotherm. Wipe off any excess. Do not be concerned if the micro does not completely reach the surface. That void can be filled immediately before skinning the part.

FLOX

Flox is a mixture of cotton fiber (flocked cotton) and epoxy. The mixture is used in structural joints and in areas where a very hard, durable buildup is required. Flax is mixed much the same as dry micro, but only about two parts flock to one part epoxy is required. Mix in just enough flax to make the mixture stand up. If "wet flax" is called out, mix it so it will sag or run.

When using flox to bond a metal part be sure to sand the metal dull with 220-grit sandpaper and paint pure mixed epoxy (no flax) on the metal part.

BONDO

Throughout these plans the term "Bondo" is used as a general term for automotive, polyester body filler. Bondo is used for holding jig blocks in place and other temporary fastening jobs. We use it because it hardens in a very short time and can be chipped or sanded off without damaging the fiberglass. Bondo is usually a dull gray color until a colored hardener is mixed with it. The color of the mixture is used to judge how fast it will set. The more hardener you add, the brighter the color of the mixture gets, and the faster it hardens. This simple guide works up to a point where so much hardener is added that the mixture never hardens. Follow the general directions on the Bondo can for fast setting Bondo. Mixing is done on a scrap piece of cardboard or plywood (or almost anything), using a hard squeegee or putty knife. A blob of Bondo is scooped out of the can and dropped on the mixing board. A small amount of hardener is squeezed out onto the blob and then you mix to an even color. You will mix the blob for about one minute. You will then have two to three minutes to apply ft before it hardens.

Be sure to clean the board and putty knife off before the Bondo is completely hard. MEK will clean Bondo off your putty knife and squeegee if it isn't completely hardened.

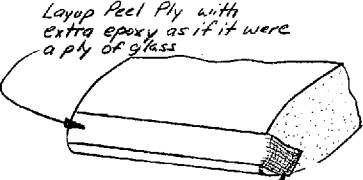

PEEL PLY

Peel ply is a layer of 2.7oz dacron fabric which is laid up over a fiberglass layup while the fiber-glass is still wet, and is later removed by lifting an edge and "peeling" it off. The most convenient form of dacron to use is "surface tapes", normally used in covering fabric aircraft. These are available in rolls. You will need at least one roll, 2" wide. Peel ply is used for two purposes:

- Peel ply any area that will later be structurally attached to another fiberglass layup. Once the dacron is peeled off, the surface is ready for another layup, without sanding. If you do not use peel ply, you will have to sand the surface completely dull (no shiny spots). This sanding is hard, itchy work and ruins the strength of the outer ply of fiberglass.

Note that to peel ply the trailing edge overlap area, the peel ply is the First ply made to the foam

core. Lay a strip of dacron down on the overlap notch and secure it with tacks or staples so it doesn't move when you layup the skin.

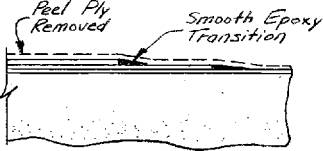

- The second use for peel ply is to transition the area where the top ply of a layup terminates on the fiberglass surface.

Refer to the adjacent sketches. If the top ply edge is laid up bare it results in a rough edge that can delaminate if a little dry. Sanding the rough edge is hard, itchy work and usually results in damaging the adjacent surface. If the edge is overlaid with a

strip of dacron during the layup (lay on the dacron and wet out by stippling or squeegeeing) it will make the edge lay down flat and will form a wedge of epoxy to smoothly transition the edge. After cure,.peel off the dacron. The result is a beautifully transitioned smooth edge with no delimitation tendency. Use this method in all places where a cloth edge terminates on the surface.

FOAM

Two different types of rigid, closed cell foam are used. Last-a-foam sheets in various thickness of about 4.5 lbs per cubic foot and polyurethane sheet of about 2 lbs per cubic foot density. Do not substitute foams for those recommended for the Super2. Getting the wrong material for your airplane can result in more work and/or degraded structural integrity. Since sunlight can damage foam, avoid exposure of foam to the sunlight by keeping it covered.