Bonding the Vertical Stabilizer into place

It is time to permenatly bond the vertical fin into place. We

will use the line that was drawn on the top of the horizontal stab

as our aircraft centerline reference. You can use the laser

level to paint a line down the center of the airpane to insure that

the line is in fact properly place.

Step 1: We need to remove the inner skin and foam at the very back

of the fuselase to make room for the vertical spar. Place a mark

on the inside of the rear fuselage about 3/8” from the rear

edge.

Mark forward location of vertical spar

Step 2: Cut only the inside fiberglass skin along this line and

remove it and the underlying foam. A dremel tool with a cut

off wheel is the easier way to get into this tight space.

Inner skin and foam trimmed Away

Step 3: Position the vertical stab so that the rear spar fits into

the slot in the rear fuselage. The vertical spar was left

long and needs to be trimmed to fit into the rear fuselage. It

is OK of it fits loosly, we want a bit of room to allow adjustment

of the vertical fin.

First Test Fit of the Vertical Fin

Step 4: locate the vertical fin bottom panel. Remember that

piece that was not used earlier when building the vertical fin? Using

the centerline on the horizontal stab, position the part on the horizontal

stab and center it. The rear edge of the notch in the part is located

2.125” from the horizontal trailing edge. Notice that

the skinner edge goes forward.

Lower Vertical Fin Panel

Step 5: Once you have positioned the lower vertical

fin panel on the top of the horizontal stabilizer as outline above,

mark its outline with a pencil. Now is also a good time to

test fit the lower panel to the bottom of the vertical fin and make

sure it fits properly.

Lower Fin Panel Location Marked on Horz Stab

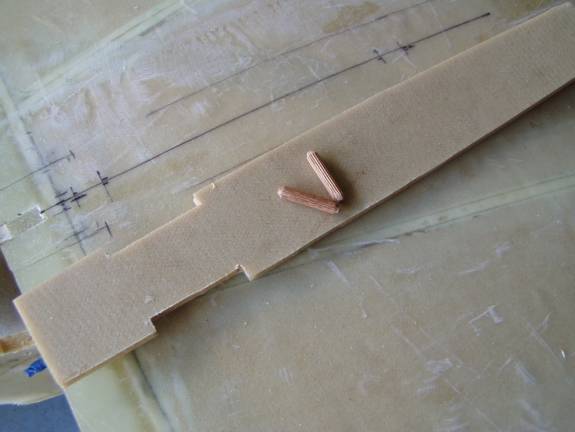

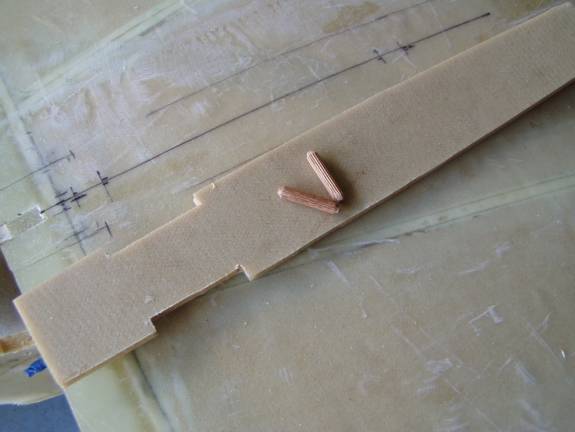

Step 6: Obtain some ¼” wooden dowels. Label both

sides of the Fin bottom panel as top and bottom. As soon as

we place out dowel pins we do not want to get it flipped upside down.

Wooden Dowel pins

Step 7: Drill two ¼” locating holes through the vertical

bottom panel and into the horizontal stab for the locating pins.

Locating Pins Installed

Step 8: Prepare the bottom of the vertical stab to accept

the bottom panel. Dig out an 1/8” of foam from the bottom

of the vertical stab sides.

Remove foam from vertical fin sides

Step 9: Mix a thick batch of micro and fill the bottom

edges of the vertical fin.

Thick Micro

Step 10: Secure the vertical fin bottom panel in place and let the

micro cure. Use Duct tape to hold the panel in place. Insure

that you do not have the panel installed upside down—if so

your alignment holes will be out of wack.

Duct Tape holding bottom panel in place

Step 11: Use some of the thick micro to secure the mounting pins

in place in the horizontal tail.

Dowel Pins Installed in Horizontal Stab

Dowel Pins Installed in Horizontal Stab

Step 12: Once the micro has cured and the bottom panel is secure

on the vertical fin, trim the bottom edge of the fiberglass

skin on bottom panel and remove 1/8” of foam. We want

to create a radious on the bottom edge to wrap fiberglass.

Step 13: Mix up another batch of micro and create a radius along

the bottom edge of the vertical fin.

Step 14: Place a 2 layer BID laminate around both sides along this

edge. Let cure

Step 15: If required, clear the holes on the bottom of the vertical

for the alignment pins and test fit the vertical fin on the aircraft.

Step 16: Like you did with the horizontal stab, establish a method

to hold the vertical fin in proper place while it is bonded in position. A

strap run over the top and to the ends of the horizontal stab works

well. Use a laser level to insure the vertical fin is in fact

perfectly vertical and properly seated against the horizontal stab. Look

from the rear and insure it is properly spaced between the two fuselage

sides.

Step 17: Remove the vertical fin and clean all surfaces to be bonded: the

top of the horizontal stabilizer, the bottom of the vertical fin,

the lower sides of the vertical fin spar and the rear inside section

of the fuselage.

Step 18: When you are satisfied with its location and can hold it

in place for a cure, mix up a batch of thick flox with your laminating

epoxy. Smear this mixture into the rear of the fuselage sides.

Step 19: Now mix up a batch of structural adhesive, the stuff you

used to bond your horizontal stab into place, and apply it to the

top of the horizontal stab and the bottom of the vertical stab.

Step 20: Return the vertical fin to its final position and secure

it with the straps. Pack more flox into the area at the rear

of the fuselage and wipe away the excess from the inside, using the

access panel hole in the side of the fuselage. Attempt to create

a reasonable radius on the inside of the fuselage where the spar

fits.

Let cure.

Step 21: Apply a four layer laminate on the inside of the fuse overlapping

the fuselage side and the forward side of the vertical fin spar.

Step 22: Apply a two layer laminate along the jont between the vertical

fin and the horizontal stab. You will need to create a radius

with thick micro first.

Let Cure—wow it is really beginning to look like an airplane!

…

|

Dowel Pins Installed in Horizontal Stab

Dowel Pins Installed in Horizontal Stab