|

|---|

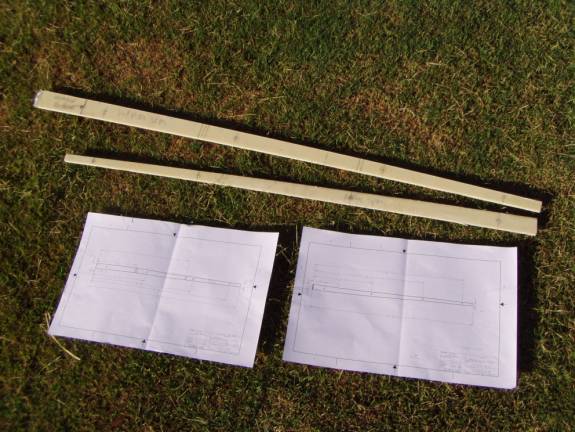

Vertical Stabalizer The first thing to do is to print out the plans for the vertical stabalizer parts and cut them from a panel of prepared foam and glass sandwich.

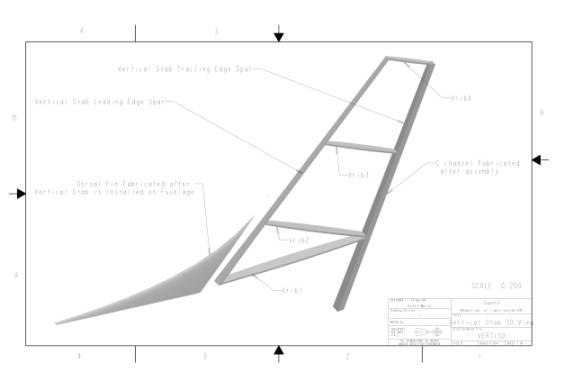

Print out the above drawings and study the 3D view plan. The vertical Stab Ribs sheets will need to be glued together into a single sheet and will provide a full size template for the ribs. The same is true of the vertical stab lower support sides. Print out all three sheets and join them at the A and B lines to form a full size 1:1 template for the vertical stab sides. The required parts are:

All parts, with the exception of the two vertical stab sides, are cut from 1/4" foam with a single layer of BID of each side. The two vertical stab sides are made from 1/4" foam with a single layer of BID on the inside. Be sure to cut a right and left vertical stab side.

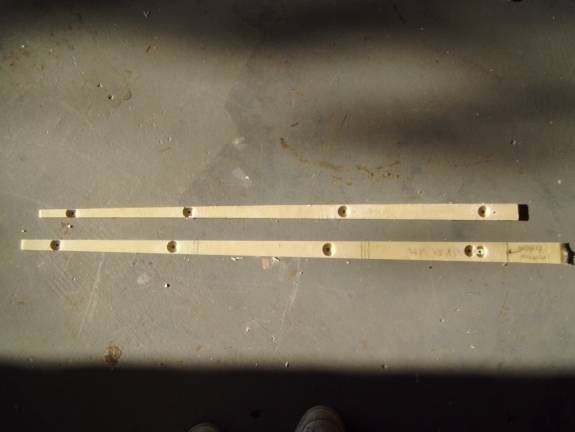

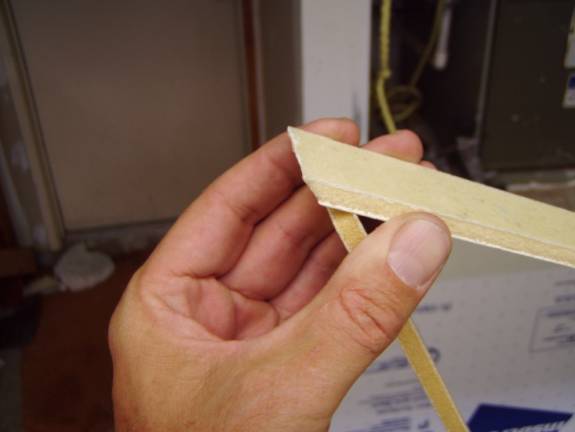

The technique used to create the three spars is the same as those used to create the horizontal stab and elevator spars. There should be enough material left over from the single sheet of 1/4" dual glassed foam that was used to cut the horizontal spars from, to cut the vertical spars. The only significant difference is that the vertical leading edge flares at the bottom due to the thickness of the dorsal fin.

Once the spars are cut out, mark the location of the ribs and hinge holes on them. Label the front and back of them.

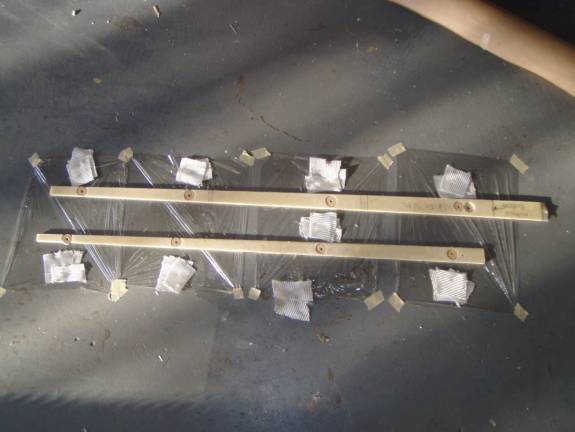

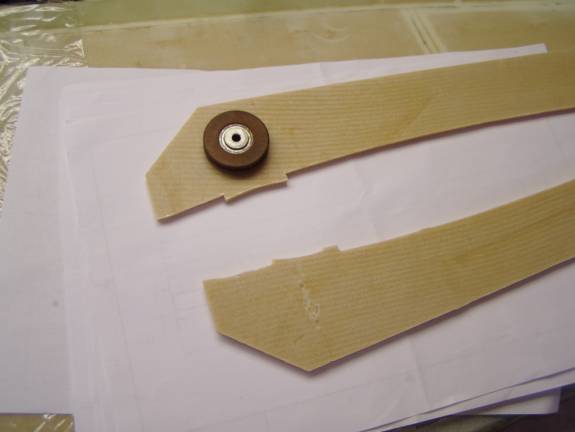

Locate and drill the forward glass out of the vert stab spar and the rear glass of the rudder spar for the hard points. Refer back to the hard point installation of the horizontal spars for the methodology used if needed.

Install hardpoint buttons in the rear vertical stab spar and the rudder spar.

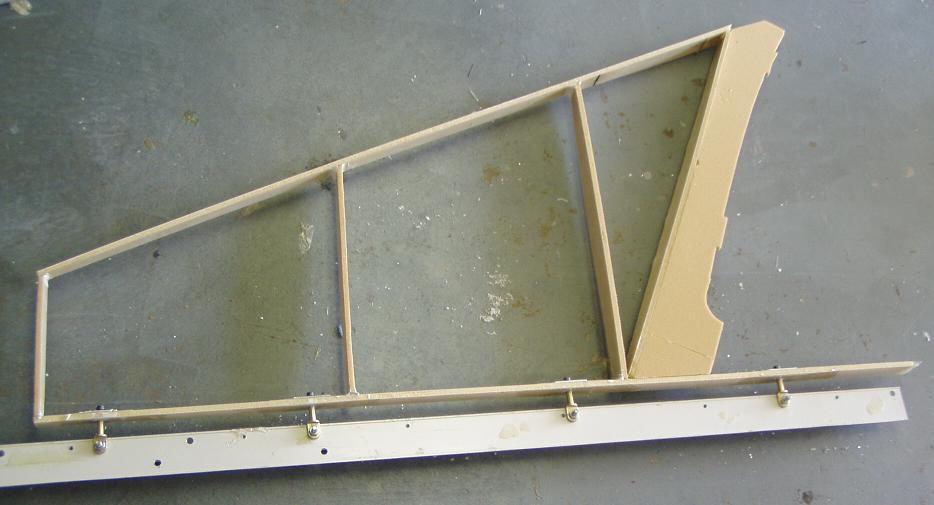

Finish the spars and install the nut plates in the vertical spar trailing edge. Do not install the nut plates in the rudder spar at this time. The position of the nut places vertically is not aboslutely critical as the rudder spar will be made to match. Insure that the eyebolt is centered in the spar side to side, however. Set the parts for the rudder aside for now. These include the rudder spar and the two rudder ribs. At this point you are ready to assemble the vertical stab frame. Refer to the 3D drawing to get an idea of how the parts fit together. The spars should already be labeled front and back and should have the locations of the ribs marked on them. Trial fit the parts together. The ribs will need to be trimmed slightly to allow for the slanting angle of the two spars.

Notice how the two lower ribs come together at the rear spar. You can also refer to the photo at the very top of this page to get an idea of what we want to end up with.

Notice how the forward spar is trimmed at an ange as it meets rib1, the lowest rib. Clamp the rear vertical spar to the work surface or to an angle as I did to insure the rear spar remains true. Once you have satisfied yourself that the ribs fit correctly, tack them into place with 5 minute epoxy or CA glue (super glue). Insure that the ribs are mounted 90 degrees to the rear spar.

Then add a small thick micro radius to the joints between the ribs and the spars. Finally use a 2 layer BID layup to join the ribs and spars to form the vertical stab frame. It is now time to reinforce the forward end of the vertical stab sides for the top elevator control cable pulley.

The above photo shows the approximate location of the upper elevator cable pulley that will be installed inside the vertical fin.

Apply two layers of BID on the forward inside side (glassed side) of the lower vertical stab sides in the area shown. Using your drawing of the vertical stab sides mark and drill 1/8" pilot holes in the locations for the pulley and the cable keeper. Drill these holes through both sides at the same time to insure the holes are lined up on both sides. Position the two vertical sides into place below the bottom most rib and between the front and rear spars. Refer to the photo at the top of this page for the proper positioning of the sides. Remember to place the glassed sides in and the foam sides out. The sides need to be bowed outward to conform to the shape of the bottom rib. Use the vertical stab bottom rib as a guide to insure the correct shape for the sides. Do not attach the bottom most rib at this time, it is the large rib with the matching tabs to the sides notches. Use CA to tack the sides into place, remove the bottom rib. Use thick micro and a two BID layup all around the inside joint of the sides to the forward spar, rib1 and rear spar. Keep this neat as the elevator cable passes through this space. It is a little tight working on the inside, so take you time. Next we will add foam to fill the spaces of the vertical stab, install the comm antenna and glass it.

PREVIOUS<---------------Manual Home ------------------>NEXT |