| |

|

Home

The Manual

Downloads

Contact

Disclaimer |

|

|

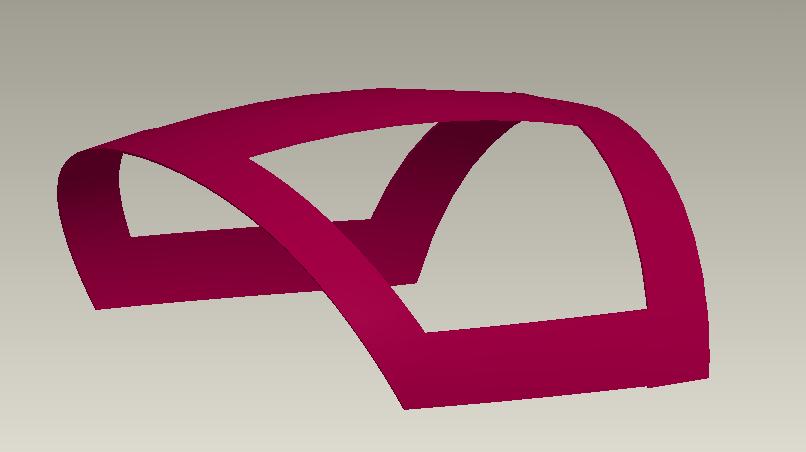

Gull Wing Canopy Inside Glass Skin

Once we have installed all of the foam as described

in the last section we are ready to prep for glassing the inside

skin. The

foam needs to be sanded and all edges need to have a slight taper

to them and all corners need to be knocked down. The carbon fiber

cloth will have to follow some fairly complex shapes and we want

to insure that there are no voids or air bubbles under the layup.

Carbon fiber is not clear like fiberglass and we will not be able

to see the voids. Let us start off with a photo of the final result. Notice

the detail of the inner skin around the hinge brackets. The zone

between the door bracket and the frame bracket is not covered with

inner skin.

Finished Inner Skin

Before we move on lets review from the last section and insure that

our foam is prepared properly. . The following photos

show the foam prepped and ready for the inner skin. Review from the

last section, the foam must:

- The edges have a slight tapered to them, no vertical surfaces

- The outside corners have been sanded to have about a 1/8” radius – no

sharp corners

- All of the inside corners have been filled in with micro, again

1/8” radius – no sharp corners

- The outside skin is cleaned and free of micro for the inside

skin to bond to.

Micro in the corners form a nice radius

Exposed outer skin for inner skin to bond to

Preping for inner skin

If you are going to use vacuum bagging to apply the inner skin (I

did not) you need to apply the inner skin in small, manageable sections

and use the technique shown above to seal the ends. Masking

tape is applied on the boundary of the area of the layup and this

is used as a vacuum seal surface.

Nice radius all around the corner of the canopy door

The inner skin is 3 layer of Carbon Fiber BID. It

is best to glass the inside of the canopy in manageable sections

that are overlapped. Use peel ply as the top layer (be sure

to remove after cure, of course) to insure each layer makes a good

bond to the previous one.

3 layer carbon fiber inner skin

Cut the carbon fiber for the center roof section, the front and

rear bows. If you have prepped the foam well, the carbon fiber

lays down well.

Carbon fiber for bows inner skin

Rear bow inner skin

Roof section and rear bow covered

Rear roof section/rear bow interface ready for inner skin

Front bow ready for inner skin

Completed inner skin.

PREVIOUS<---------------Manual

Home ------------------>NEXT |

|

|

|

|

|