Fabricating and Installing the Canopy Hinges.

The canopy hinges consist of rod ends and an eye bolt on custom

fabricated brackets. The following material is required:

2 feet of 2” X 2” X 1/8” 6061-T6 aluminum angle

4 each rod ends MM-4

4 each eye bolts AN44-14A

4 each washers

4 each washers

4 each nut plate K1000-4

4 each nut plate K1000-5

4 each an4-7A bolt

4 each AN365 nut

4 each washer for hinge point

Rivets

milled fiberglass

epoxy

32 screws AN507-10R8

32 1032 fiber lock nuts AN364-1032A

washers

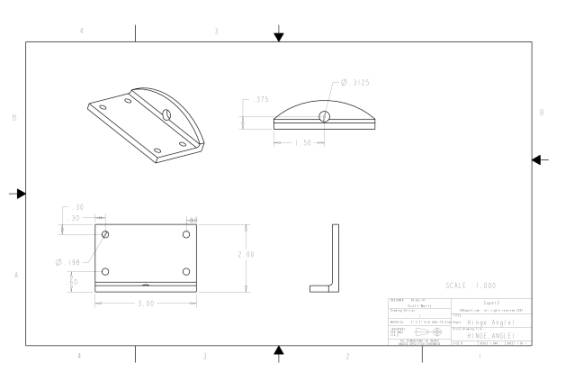

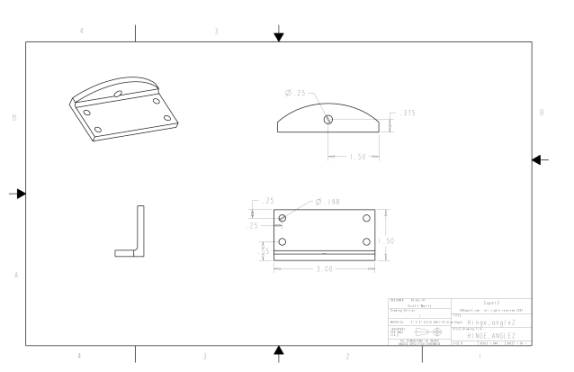

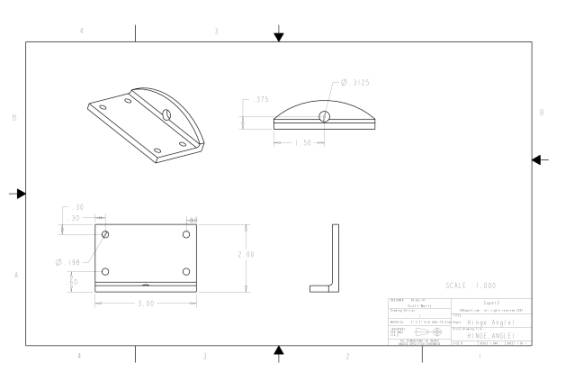

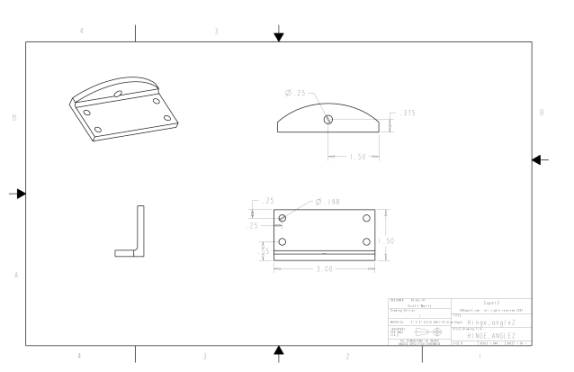

The canopy hinges are fabricated from a 2 foot piece of 2” X

2” X 1/8” 6061-T6 aluminum angle. Print out

the following drawings and plan to make 4 canopy

frame hinge brackets and 4 canopy

door hinge brackets.

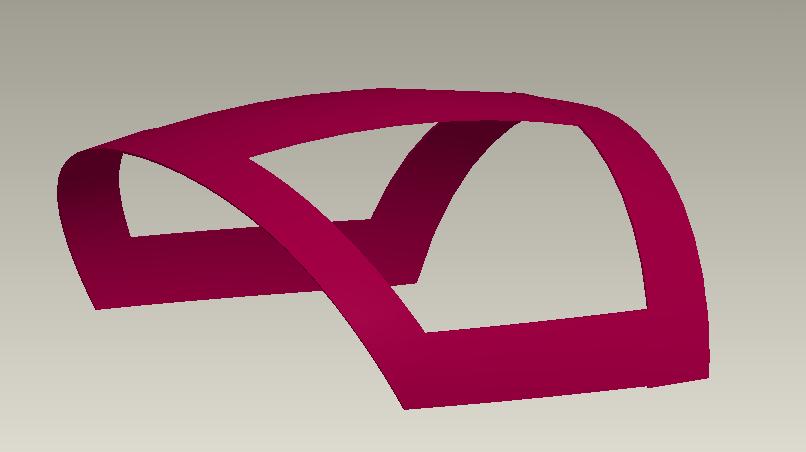

Canopy

Door Hinge Bracket Drawing Canopy

Door Hinge Bracket Drawing

Canopy frame bracket drawing

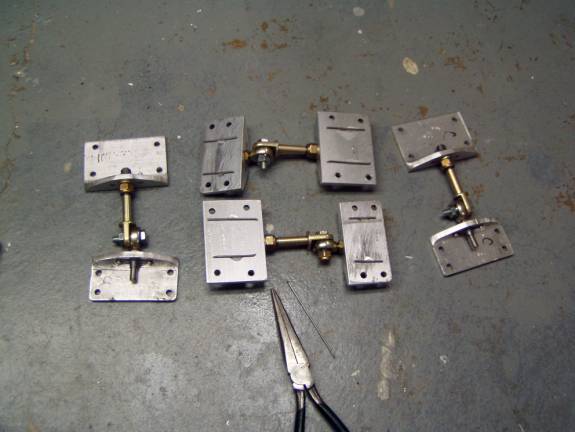

Cut 8 each 3 inch inch lengths from the angle stock. Use the

1:1 drawings to locate the holes and drill them as specified. Finally

shape the hinge brackets to size.

Rivet the K1000 nutplates in place.

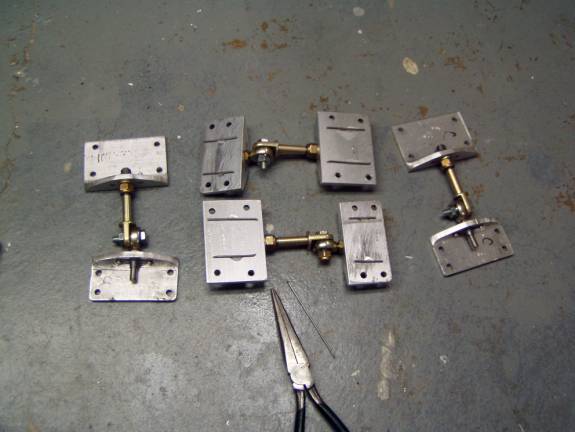

Install the rod bearings with the AN316-4 thin nuts to the

canopy door hinge bracket. The rod bearing should be threaded

all the way in.

Install the eye bolt with the washer to the canopy frame bracket.

Use the AN4-7A bolts, washers and AN365 lock nuts to secure the

two halves of the hinge together and adjust the length of the eyebolt

so that the opposing faces of the hinge brackets are about 2 5/8” inches

apart.

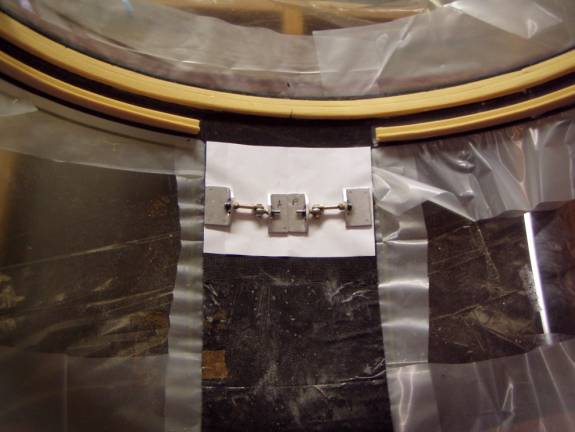

Completed Hinge assembly

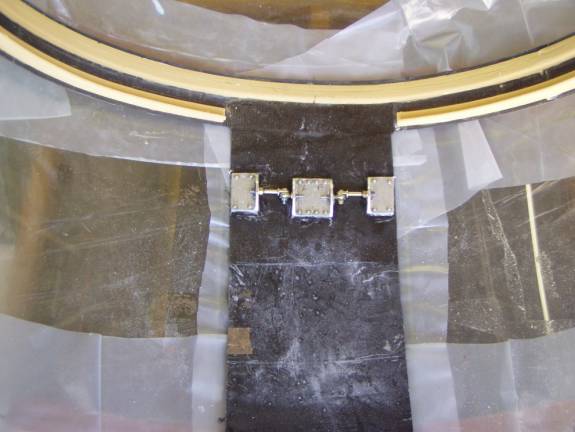

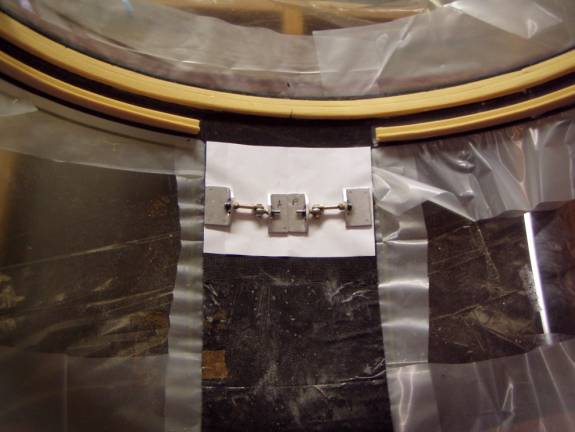

Now position the completed hinge assembly into the canopy frame

as shown below. The two front hinge assemblies are installed

first. The forward mounting holes of the hinge brackets are located

4 inches back from the rear edge of the forward bow. Insure

the hinges are square, the two center brackets are touching, and

then drill the 16 holes through the carbon fiber canopy top. Notice

that the eye bolts are oriented toward the front.

Proper location of hinge assemblies

We will now permanently mount the hinges to the canopy top. We

want to solidly bolt the hinge assemblies to the canopy frame, but

do not want to deform the shape of the carbon fiber skin. We

will create a mounting pad under the hinge from milled fiber glass

and epoxy resin. First we will CA glue small pieces of 1/16” music

wire to the bottom of the hinge brackets to act as spacers.

Wire CA glued to bottom of hinge brackets

Prepare the screws and nuts by soaking them in a mold release solution. Use

AN507-10R8 screws and AN364-1032A lock nuts.

Soak the nuts and screws in a mold release

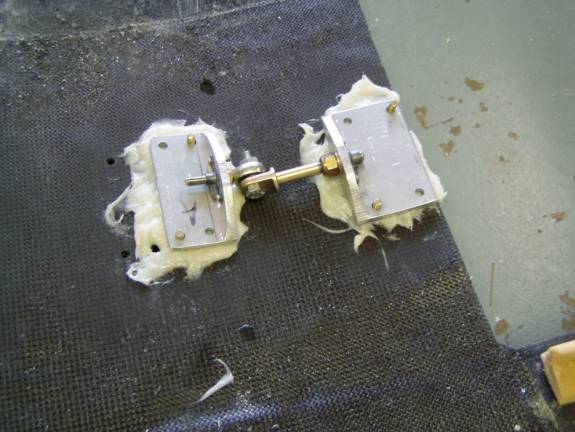

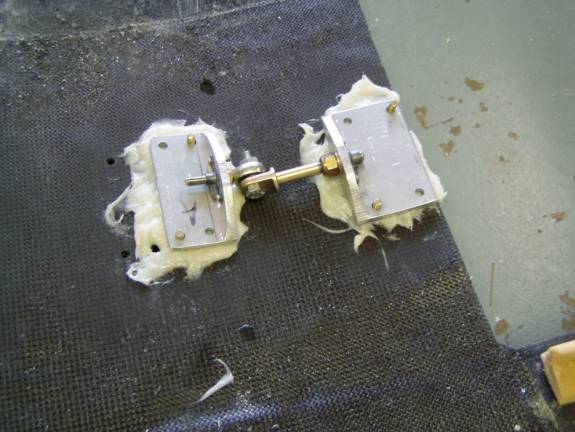

Mix up a thick batch of milled fiberglass and epoxy resin. Smear

this mixture on the inside of the canopy frame and install the

hinge brackets with the screws and nuts.

Thick milled fiberglass misture

The screws and nuts should be very lightly tightened. We want

absolutely no deformation of the canopy skin, but we do want the

hinges seated down against the skin.

Let the milled fiberglass mixture ooze out.

Wipe away the excess milled fiberglass mixture and inspect the edges

of the hinge brackets to insure they are evenly seated. Do

not over tighten the nuts.

Install all of the screws and nuts.

Let the Milled fiberglass mixture cure.

Remove the screws and nuts. Counter sink the holes on the

top side of the canopy skin and reinstall the screws and nuts. This

time you can torque the screws down and no deformation should occur.

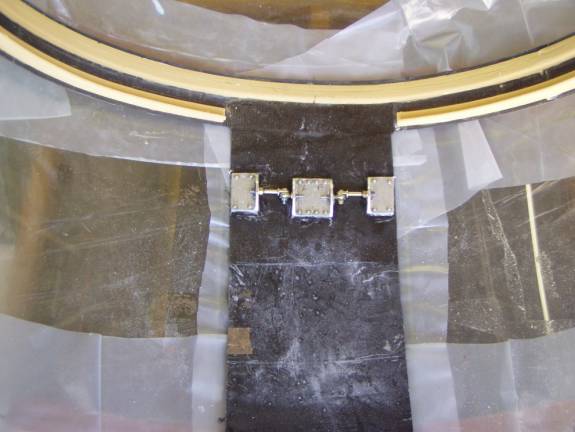

Hinges completely installed.

Repeat the process for the rear hinges. The rear most mounting

holes of the rear hinge assemblies are located 4.25” inches

in front of the front edge of the rear bow.

All hinge brackets are installed

PREVIOUS<---------------Manual

Home ------------------>NEXT |