Rear Control Tunnel

The rear control tunnel encloses the rudder cables and elevator

control tube that pass down the center of the aircraft and would

otherwise be exposed through the baggage compartment. Wiring

for the elevator trim, position lights, antenna cables as well as

the static line also run down through the control tunnel.

By this point in the Super2 construction you are quite familiar

with the construction techniques employed. I no longer need to be

as explicit in the details of constructing each part.

Print out the drawings for the rear control tunnel sides and create

a full sized template. There are four drawings that need to

be taped together at the vertical reference lines.

Create

a left and right side using ¼” last-a-foam

with one BID on each side. Drill the three pilot holes in each

part.

Rear Control Tunnel Sides

Notice that there are three holes located on each part toward the

rear. The center of these is the pivot point for the elevator

bellcrank. The remaining two holes are for through bolts that

act as control stops for the elevator.

Rear Hole Locations

Mark the two sides so you don’t end up making two right sides.

Identify each Side

Reinforce the rear holes with wooden buttons using the technique

we have already mastered.

Reinforcement Preparation

Cut a couple 3” spacer blocks from scrap 2X4 and place between

the control tunnel sides.

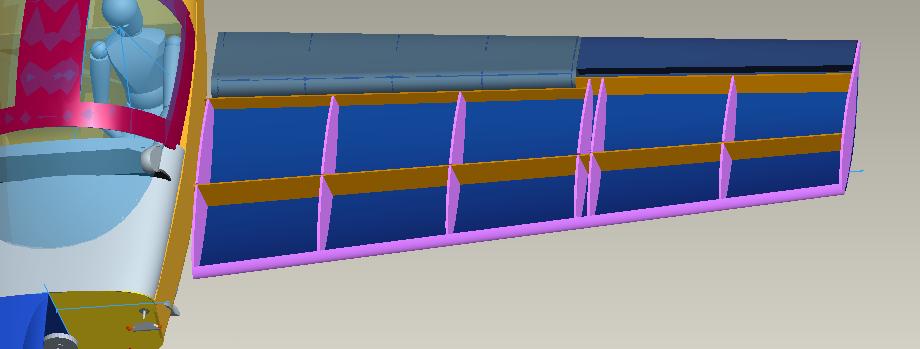

Control Tunnel Installation

Position the rear control tunnel inside the fuselage. The

forward edge should contact the very bottom of the seat and the rear

sides of the control tunnel should fit into the slot of the baggage

bulkhead. The control tunnel should be centered down the middle

of the fuselage.

Close up of 3” spacer Block

Note: There is a pivot point shown in the above photo that

is no longer used. This was a mounting point for the rudder

cable pulley that has been moved forward in the final design. Please

disregard any visual reference to this feature.

Use CA to tack the control tunnel into position. Tack it to

the baggage bulkhead and the floor of the fuselage. Do not

tack the control tunnel sides to the seat back.

View of Aft end of Control Tunnel

Remove the spacer blocks and secure the control tunnel into position

with a single layer of BID along the interface to the fuselage floor

and the baggage bulkhead. Remember to clean the surfaces and

apply a micro radius. Do not bond it to the seat back Let cure.

Mark the seatback where the inside of the forward edge of the control

tunnel sides met it as shown below. We will need to remove

a section of the seat back to allow the elevator push tube to pass.

Mark tunnel contact on Seat Back

Fabricate the control tunnel top by starting with a 3.5” wide

piece of ¼” last-a-foam the full length of the control

tunnel. Layup a one layer BID on the bottom side of the foam.

Trim the edges of the resulting part to match the sides of the control

tunnel. Sand a radius along the sides of the top.

Apply packing tape along the top sides of the control tunnel as

a release film. Layup a one BIB fiberglass over the top of

the control tunnel lid and overlap about an inch onto the control

tunnel sides. Let cure.

Remove the control tunnel lid and trim the resulting flanges to

an even 1”. Remove the packing tape from the sides of

the control tunnel.

Control Tunnel Top Cover

.

.

PREVIOUS<---------------Manual

Home ------------------>NEXT |